Orca design: behind the scenes

Designing the world’s first mass-production electric personal watercraft is no small feat. But for the talented designers and engineers here at Taiga, it was a welcome challenge. With no prior experience developing gas-engine vehicles, we started with a blank page. The result—the Orca watercraft—is like nothing else on the market.

“It might not be obvious to the naked eye, but we’ve done a lot of work on optimization,” says nautical platform engineer Clovis Roy-Bernier, who led the design of the Orca’s hull. After completing a master’s degree in maritime engineering in England, Clovis jumped at the opportunity to join the Orca design team at Taiga. His passion for boats stretches back to his childhood in eastern Quebec’s Gaspésie region: “I grew up by the sea and began sailing at age five. I’ve always loved the water,” he says.

Similarly, mechanical designer Moran Le Calonnec has been fascinated by vehicles for as long as he can remember. Having studied both engineering and industrial design, he brings a mix of practicality and creativity to his work. “At the beginning, we try to do things that are the most impressive, the most beautiful,” he says. “Afterwards, we streamline the design to turn it into a product we can actually make and that the customer will recognize.”

For the Orca, we drew inspiration from a variety of sources, including the experience of being in nature. “I go hiking often, and I’m bothered by the noise of snowmobiles and jet skis,” Moran explains. “Our products are more discreet, and we try to convey that in the design.” The result is a watercraft that looks as sleek as it is quiet.

“Being electric is an opportunity to explore or innovate when it comes to designing the vehicle or even the accessories,” adds senior industrial designer Sergio Mora.

The Orca watercraft’s seats are a good example of this: since there is no combustion engine taking up space underneath the seats, there’s more room for accessories and other functions that may be developed for future models.

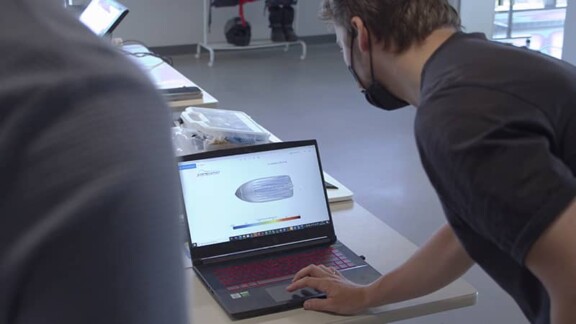

By taking a clean-sheet approach to designing the Orca watercraft, we were also able to optimize every aspect of the hull. As the component that allows the watercraft to float and remain stable and manoeuvrable at different speeds, the hull has a major impact on the vehicle’s overall performance. Before building a prototype, we used computer simulations to test how the Orca would perform in the water and refined the shape of the hull to decrease resistance and maximize speed range.

The Orca’s hull and deck are both made of carbon fibre, and this stiff, lightweight material was key to achieving the desired shape and weight for the watercraft. “If we want to achieve the autonomy we’re aiming for, we have to be able to reduce the maximum weight,” explains Clovis. “Carbon fibre is the best material for that purpose.”

According to Clovis, the Orca watercraft is unique in that it combines the best elements of the smaller and larger models available on the market.

“With the Orca, we’ve created something that’s very nimble, very manoeuvrable at low speed, but that can also reach high speeds and remain stable.”